Flatlift Point is Elevating the Game with New Look.

The Spaldings SPL Ultra range features various Flatlift® parts. Based on customer feedback, the Spaldings Product Development team examined part number 02154 with a view to making improvements - considering wear patterns observed during customer trials and usage.

The new re-designed Flatlift® point now offers increased performance through:

- Built-in wear deflectors to help maintain the shape

- Chamfered holes to ease pin fitting

- 20% increase in hardness

- 30% more material for a longer lifespan

Stow Farms in Lincolnshire aimed to reduce their point usage and minimise downtime, having used 184 points over the past six years. While drilling Oil Seed Rape, the business sought improvements without investing in Tungsten-tiled versions.

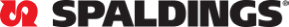

Gary Dawes of Orman (Carrolls Farms) Ltd, who farm 200 acres of heavy flint, cannot use Tungsten. With the previous point, Gary covered about four hectares before needing a change. Below, you can see the wear pattern difference at four hectares between the previous and new styles.

Below shows the wear pattern of the new style (left) to the worn old style

|  |

When trialling the new style point, Gary found it doubled the wear time of the previous version. The lower shin also showed improvement, increasing from six to eight hectares. Gary was highly impressed and recommends the new point, noting savings on replacement costs and reduced downtime.

In addition – the newly redesigned point is still at the same fantastic price point as the previous design!